Press Tool A Complete Guide to Types, Applications, Design, and Benefits

Introduction

In modern manufacturing, the demand for precision, speed, and efficiency continues to rise across industries such as automotive, aerospace, electronics, and metal fabrication. To meet these standards, companies rely heavily on specialized equipment—one of the most essential being the Press Tool. A press tool is a mechanical device used to shape, cut, form, or assemble sheet metal with high accuracy and consistency. Whether producing thousands of identical components or crafting intricate metal parts, a press tool plays a central role in ensuring the quality and reliability of the final product.

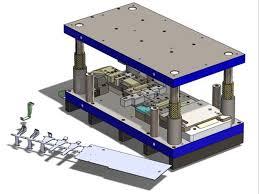

What Is a Press Tool

A Press Tool is a device installed in a press machine that performs operations like punching, blanking, bending, drawing, and forming on sheet metal. When the press applies force, the tool creates a specific shape or cut based on the design of its components. Depending on complexity, press tools may include dies, punches, stripper plates, pilots, and other supporting parts. These tools are engineered to handle repeated cycles under extreme pressure without losing precision—making them indispensable in mass production.

Types of Press Tools

There are multiple types of press tools, each designed for a particular type of metalworking operation. Understanding these helps manufacturers choose the right tool for their production needs.

Blanking Tool

A blanking press tool is used to cut out the desired shape from a sheet of metal. The cut-out piece is the final product, known as a “blank.” This tool is widely used in industries producing gears, washers, caps, and electronic components.

Piercing Tool

Piercing tools are used to create holes in sheet metal. Unlike blanking, the removed portion is scrap, while the remaining sheet is the functional part. These tools are essential in creating ventilation parts, brackets, automobile panels, and electrical enclosures.

Bending Tool

A bending press tool bends sheet metal at specific angles with perfect consistency. These tools ensure uniformity in products such as brackets, support frames, and metallic casings.

Forming Tool

Forming tools manipulate the metal to take complex shapes without breaking or cracking it. These tools are used in creating automotive body parts, kitchen appliances, and decorative metal items.

Progressive Tool

A progressive press tool performs multiple operations—such as punching, bending, and cutting—in a single stroke. As the metal strip moves through different stations, each step shapes it further until the final component is complete. For high-volume production, progressive tools are among the most cost-effective solutions.

Compound Tool

A compound press tool performs two or more cutting operations simultaneously within one station. This increases accuracy and reduces production time, making it ideal for precision components like washers, gaskets, and electronic parts.

Drawing Tool

Drawing tools stretch metal sheets into desired shapes, often creating deep or shallow cylindrical forms. These are commonly used in manufacturing cans, kitchen utensils, and automobile fuel tanks.

Key Components of a Press Tool

Several parts come together to create an efficient press tool. Each component must be designed with precision, as their performance directly affects product accuracy.

Die Block: Forms the lower half of the tool, containing the cavity where sheet metal is shaped.

Punch: Performs the cutting or shaping by applying force to the metal.

Stripper Plate: Holds the sheet metal in place and removes it from the punch after operation.

Shank: Connects the press tool to the press machine.

Guide Pillars and Bushes: Ensure alignment of the tool and prevent misoperation.

Bolster Plate: Provides support and stability.

Applications of Press Tools

Press tools are used in a wide range of industries due to their versatility and precision:

Automotive Manufacturing

From small brackets to full body panels, press tools shape the metal parts used in vehicles.

Electronics Industry

Components such as connectors, switches, and casings are mass-produced using precision press tools.

Aerospace

Lightweight yet durable metal parts for aircraft components are crafted using forming and blanking tools.

Household Appliances

Products like washing machines, refrigerators, and microwave casings rely heavily on sheet metal components made with press tools.

Construction & Architecture

Structural metal components, window frames, and roofing parts are produced using various types of press tools.

Benefits of Using Press Tools

Investing in the right Press Tool brings significant advantages to manufacturers:

High Precision and Consistency

Press tools produce thousands of identical components with minimal variation, ensuring reliability in mass manufacturing.

Increased Productivity

With high-speed operations and automated workflows, press tools significantly reduce production time.

Cost-Effectiveness

Though the initial investment may be high, press tools reduce long-term costs by minimizing material waste and reducing manual labor.

Versatility

A single press machine can perform multiple operations by switching tools, making it adaptable to various production needs.

Improved Quality Control

Press tools maintain strict tolerances, ensuring components meet exact specifications and reducing rejection rates.

Press Tool Design Considerations

Designing an effective press tool requires understanding material properties, production volume, and the type of press used. Key considerations include:

Material Selection: Tool steel, high-speed steel, and carbide are commonly used for durability.

Tolerance Requirements: High-precision dies demand tight tolerances to avoid quality issues.

Safety Features: Proper guarding and alignment systems ensure operator safety.

Maintenance Requirements: Regular sharpening and inspection prolong the tool’s life.

Conclusion

A Press Tool is one of the most powerful assets in modern manufacturing. Its ability to cut, form, bend, and shape metal with precision makes it essential across countless industries. By selecting the right type of press tool and maintaining it properly, businesses can improve productivity, reduce costs, and achieve consistently high-quality results. As industries evolve and demand more innovative metalworking solutions, press tools will continue to play a central role in efficient and reliable production.

See more our website:visit here

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness